Class Projects

Design of Mechanical Systems – Centrifugal Fan Clutch (Senior Year)

- Goals of project: given a basic system diagram and desired operating conditions for a centrifugal fan clutch, calculate all of the necessary dimensions for the shoe and spring components. Then, design assembly mating interfaces and create a CAD model with dimensioned drawings.

- Project completed with two other partners. I completed half of the calculations, all of the CAD and diagrams, and wrote the design and evaluation section of the report.

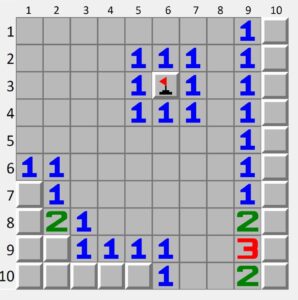

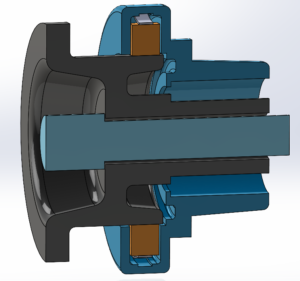

- The first image below shows a cross-sectional view of the centrifugal fan clutch CAD and the second image shows a close-up of one of the shoe and spring assemblies.

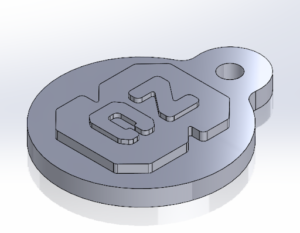

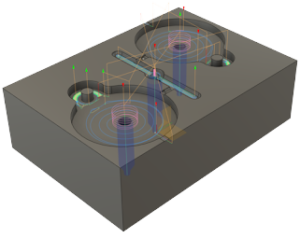

Modern Manufacturing Practices – Injection Mold Design (Senior Year)

- Goals of project: create an injection mold for a simple part. Complete all CAD and CAM, and create prototypes for both halves of the mold.

- Project completed with five other group members. I worked with one partner to complete all of the CAD and the manufacturing cost analysis.

- The first image below shows a simple NC State key chain I designed to use for the part. The second image shows one of the views from the CAM work.

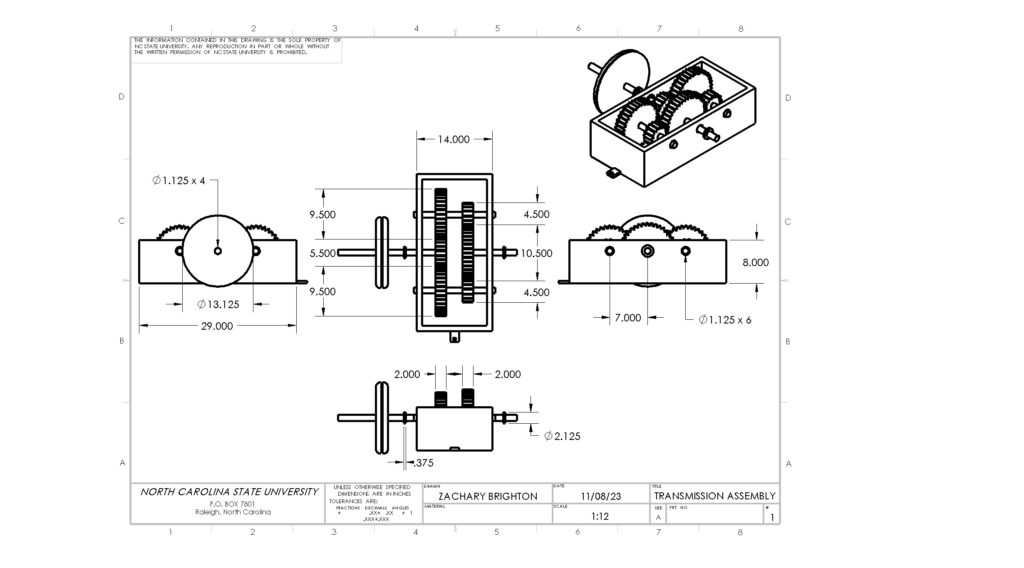

Design of Mechanical Systems – Transmission Gearbox (Senior Year)

- Goals of project: complete power, speed, and force calculations on each component in a gearbox + fluid coupling transmission setup. Use these determined specifications to select/design all of the gears, bearings, and shafts.

- Project completed with two other partners. I created the CAD assembly and worked with a teammate to share all of the calculations, diagrams, and analysis portion of the report.

- The first image below shows a dimensioned drawing of the completed transmission assembly (top half of gearbox removed for viewing access).

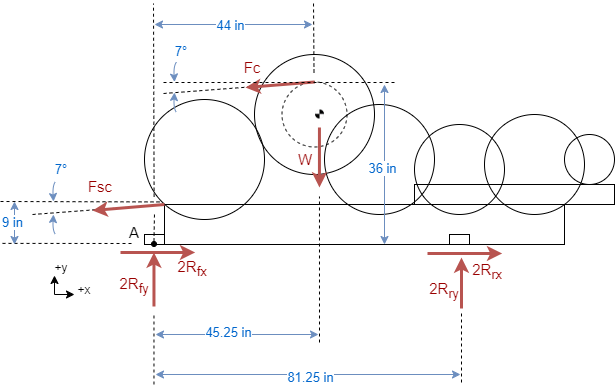

Design of Mechanical Systems – Winch Anchor Bolt Design (Senior Year)

- Goal of project: analyze a real boat winch accident shown below and design two new mounting systems: one with mechanical wedge style anchors and one with adhesive anchors to prevent future failure.

- Project completed with two other partners. I completed all of the statics calculations, helped pick out the bolts, created all of the diagrams, and wrote the analysis section of the report.

- The first image below shows the winch accident and was provided to us as part of the problem statement. The second image shows one of the free body diagrams I created for the report.

Modern Manufacturing Practices – Hand Puller For Bearing Removal (Senior Year)

- Goals of project: manufacture and assemble all of the components of the hand puller shown below using a mill, lathe, and waterjet machine. Use relevant manufacturing equations to determine appropriate feeds and speeds for the workpiece material and different cutting operations.

- Project completed with five other partners. I contributed an equal share of the manufacturing and was responsible for the calculations of my assigned part.

- Image below shows my team’s final project.

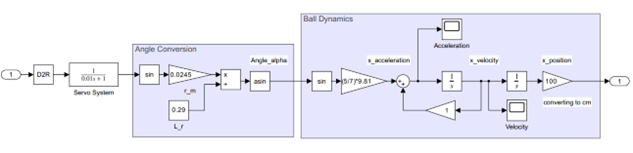

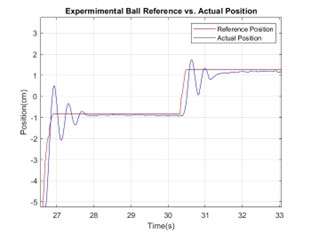

Controls – Ball and Beam Balancing System (Senior Year)

- Goals of project: design a Simulink controller to stabilize a motorized Ball and Beam system. The user should be able to input a reference location on the beam which the ball will role to and balance at.

- Project completed with three other partners. I derived all of the dynamic modeling and created the Simulink controller as well as helped with the testing.

- Link below shows final report and images are of the ball and beam system, Simulink plant, and graphical output of the ball following location commands.

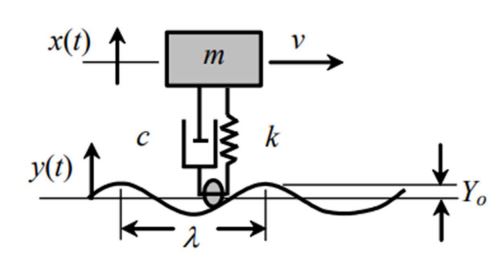

Vibrations – Landing Gear Design (Junior Year)

- Goals of project: design aircraft landing equipment values to produce lowest amplitude vibrations while keeping practical cost and resource availability in mind. Model square wave runway condition using Fourier series and compare frequency response to runway to landing gear design to check for resonance issues.

- Project completed with two other partners. I was responsible for the majority of the derivations and also helped with the MATLAB coding.

- Link below shows final report and image is a basic model of landing gear examined.

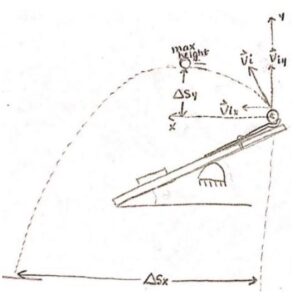

Dynamics – Rube Goldberg Machine (Sophomore Year)

- Goals of project: design system that uses several types of simple machines. Use technology to obtain experimental values and compare to theoretical values determined by modeling and dynamics calculations.

- Project completed with two other partners. I was responsible for using tracker software and doing half of the modeling and calculations as well as helping build the machine.

- Link below shows final report and images show example of one simple machine.

MAE 208 Group Project – Mr. Worldwide

![]()

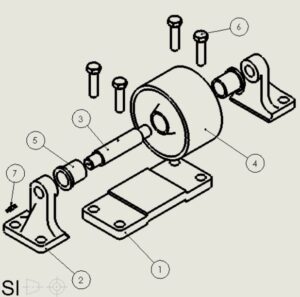

Graphics – Roller Support Assembly (Freshman Year)

- Goal of project: model parts and assembly in SolidWorks and create drawings for all.

- Project completed individually.

- Link below shows drawings turned in and image shows assembly.

Roller Support Assembly Report

MATLAB – Minesweeper Game (Freshman Year)

- Goal of project: design easy to use, randomly generating minesweeper game.

- Project completed with one other partner. We both worked together to complete all of the logic and coding.

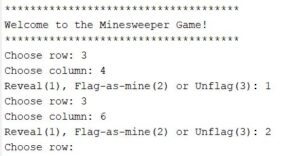

- Link below shows pdf of main code file and images show an example of game play.

Matlab Mindsweeper Project Code