School Design Projects

Senior Design Project – Caterpillar CTL Grading Display Positioner

- Goals of Project: design a new mounting system for a grading display in a Compact Track Loader (CTL, image below). Mounting system had to be easy for operator to move and store as well as resist vibrations and fatigue.

- Year long project completed the 2022-2023 academic year with a team of five. I was the team captain and helped mainly with the design, computer simulated analysis, and vibration testing as well as leading team meetings, documentation, materials research, etc.

- Team placed 1st out of six teams in the project category.

- The image below shows my team and I holding a few of our prototypes which were fabricated using sheet metal and 3D printing processes. Unfortunately no close ups of the design or details of the report can be provided as those are now Caterpillar proprietary information.

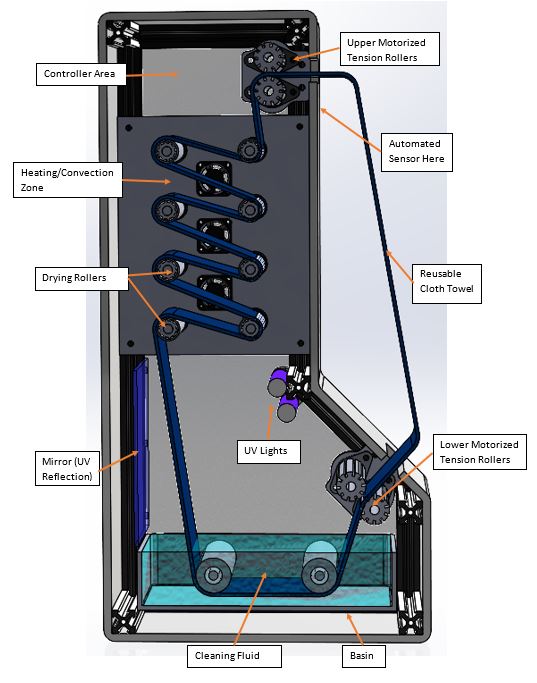

Make-A-Thon Sustainability Project – Reusable Towel Dispenser

- Goals of Project: develop and prototype a solution to a sustainability related issue during NCSU’s 48 hour Make-A-Thon competition.

- My teammate and I designed a self-sanitizing, reusable cloth towel dispenser that utilizes an internal cleaning solution, UV radiation, and a convection heating system to minimize paper towel waste in a cost effective and sanitary manner. I completed half of the research, designing, and modeling.

- Our team placed 3rd out of 27 teams.

- The image below shows our CAD modeled prototype and the link leads to an article about the event.

https://sustainability.ncsu.edu/blog/2023/01/31/waste-solutions-are-big-winners-at-2023-make-a-thon/

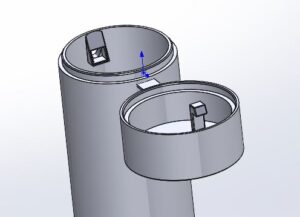

Senior Design Project (HS) – Effective Childproof Bottle

- Goals of Project: research any problem and prototype a new solution. We chose to focus on creating a childproof bottle that was easier for the elderly to use and harder for small children to accidentally open.

- Found a local professor to learn more about plastic injection molding from and did market research at a senior living facility.

- 3D printed and improved our prototype several times and showed the community during a large presentation at the end of the year.

- Project completed with one other partner. I was responsible for half of the research and documentation and the majority of the design work.

- Images below show a CAD model of the prototype.